Revolutionizing Safety in Steel Manufacturing with

Digital Twin Technology

Wistwin's Advanced Digital Twin Solution for Carbon Monoxide Risk Management

Steel manufacturing is a complex process that involves the use of various raw materials, high temperatures, and hazardous gases. Among these, carbon monoxide (CO) stands out as both essential and highly dangerous. CO is an odorless, colorless gas integral to the steel production process but presents a significant risk due to its toxicity. Any leakage of this gas can lead to catastrophic outcomes, including potential loss of life and severe production disruptions.

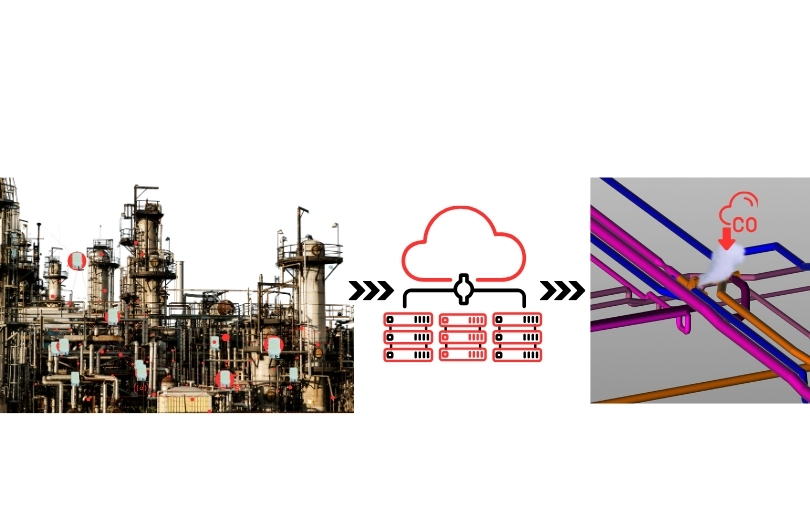

To address this critical safety challenge, VB Group has developed Wistwin, an advanced digital twin solution tailored specifically for the steel manufacturing sector. By digitizing the entire piping and process systems and integrating Industrial IoT (IIoT) sensors, Wistwin offers real-time monitoring, risk assessment, and proactive safety management powered by artificial intelligence (AI).

Through seamless integration with PLC SCADA systems, Wistwin offers proactive safety management, triggering alarms, pinpointing leak locations, and guiding safety teams with precise GPS-based navigation, ultimately enhancing safety and operational efficiency.

Clients

Challenges in Handling Carbon Monoxide in Steel Factories

Invisible Hazard

As a colorless and odorless gas, carbon monoxide leaks are difficult to detect without specialized equipment.

Rapid Spread

CO can quickly spread through pipelines and enclosed spaces, putting workers at risk.

Disaster Potential

Even a minor leak can escalate into a major safety crisis if not detected and managed promptly.

Manual Limitations

Traditional safety systems relying solely on human monitoring and basic alarms can lead to delayed responses.

The Wistwin Approach

Digital Twin & AI-Powered Safety

Key Features of Wistwin

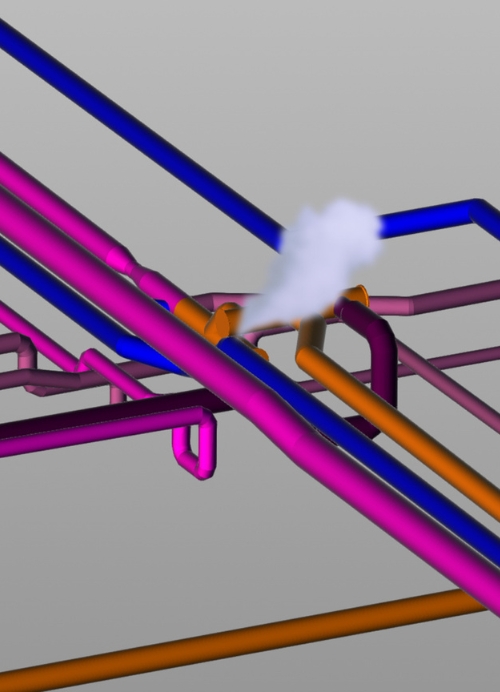

- 01. 3D Digital Twin of Gas Pipelines

- VB Group® conducted comprehensive ground data collection and meticulously developed a 3D model and digital twin of the entire gas pipeline network within the steel plant. This advanced digital replica captures every detail of the pipeline infrastructure, enabling real-time monitoring, predictive maintenance, and enhanced safety management

- 02. Automated Alerts

- When a sensor detects a gas leak, an alarm is triggered in the central command room, showing the exact location on the digital twin interface.

- 03. AI-Driven Analysis

- The AI engine analyzes the situation, assesses safety risks, and recommends immediate action to mitigate hazards.

- 04. Automated Response

- Wistwin can identify the root cause of the leak, provide instructions to shut off valves, and suggest corrective actions to maintenance teams.

- 05. GPS Integration

- The platform not only identifies the leak location but also guides the nearest safety officer to the site using precise GPS navigation.

Benefits Delivered by Wistwin

Life-Saving Response

Operational Continuity

Client Success

Case Study: Enhancing Safety at Steel Factory

Background: Steel Factory, a leading steel manufacturer, faced challenges in ensuring safety around their extensive CO pipeline network. Previous incidents had exposed gaps in manual monitoring systems, highlighting the need for a more advanced safety solution.

Implementation: VB Group conducted a thorough data collection and digitized the entire piping and process systems of the facility. Over 100 IIoT CO detection sensors were installed along critical points of the pipeline. The central command room was set up with a fully integrated Wistwin platform, seamlessly connecting to the factory's existing PLC SCADA system.

Outcome: Within the first few months of deployment, Wistwin detected a minor CO leak near a critical production unit. The system's AI-driven analysis triggered an immediate alarm, provided actionable recommendations, and guided the safety team to the exact location. This swift action prevented a potential disaster, avoided production downtime, and reinforced the safety protocols of the facility.

Enquire NowConclusion:

VB Group's Wistwin platform is a game-changer for the steel manufacturing industry, providing a robust, intelligent, and proactive approach to managing the dangers of carbon monoxide. By combining digital twin technology, IoT, and AI, Wistwin not only saves lives but also enhances operational efficiency and offers unparalleled support to safety departments. As the steel industry continues to modernize, solutions like Wistwin will play a pivotal role in driving sustainability, safety, and success.