VB Group's Digital Transformation Success Story: Leading the Global Industrial IoT Revolution for Greenhouse Maintenance

Introduction: Redefining Greenhouse Maintenance with Wistwin Digital Twin and Industrial IoT

VB Group's Digital Transformation Division has achieved a groundbreaking milestone in the industrial IoT (IIoT) domain by developing a home-manufactured IIoT device specifically designed for greenhouse maintenance. This revolutionary solution, embedded seamlessly into the Wistwin Digital Twin platform, has positioned VB Group as a global leader in industrial IoT solutions. With integrated ambient sensors and AI-driven predictive analytics, the system has significantly improved operational efficiency, increased yield, and reduced abnormal shutdowns in greenhouse facilities worldwide.

The Challenge: Optimizing Greenhouse Operations with Minimal Human Intervention

Greenhouses play a vital role in controlled environment agriculture. However, maintaining optimal conditions for plant growth requires continuous monitoring of ambient parameters such as CO2 levels, temperature, humidity, illumination, and oxygen concentration. Traditional greenhouse monitoring systems lacked automation, real-time data collection, and AI-driven recommendations, leading to inefficiencies, increased downtime, and reduced productivity. Additionally, human-dependent monitoring made the process labor-intensive, error-prone, and time-consuming.

Clients

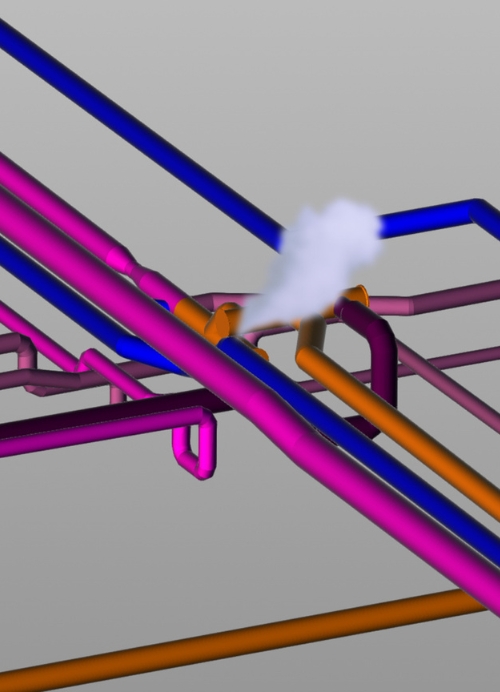

Innovative Home-Manufactured IIoT Solution Integrated with Wistwin

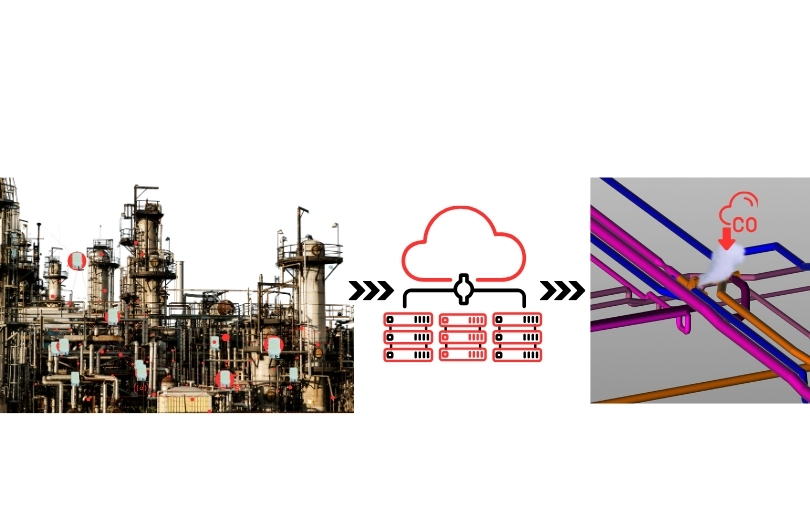

To address these challenges, VB Group’s Digital Transformation Division engineered a state-of-the-art IIoT device tailored for greenhouse maintenance. The device was designed and manufactured in-house, ensuring complete customization to meet the specific needs of greenhouse operations. The core components of the solution include:

Ambient Sensors

Equipped with CO2, temperature, humidity, illumination, and oxygen sensors, the IIoT device continuously monitors the greenhouse environment.

Centralized Server Gateway System

The IoT devices installed across all greenhouses are integrated with a centralized server, enabling seamless data transmission and analytics.

Abnormality Detection and Alerts

The system automatically detects abnormalities and notifies supervisors with real-time recommendations to restore optimal conditions.

AI-Powered Predictive Analytics

Integrated with AI algorithms, the system provides predictive insights for yield improvement based on historical data and real-time environmental conditions.

Remote Operation and Cloud-Based Monitoring

Greenhouse supervisors can remotely monitor and manage their facilities from anywhere in the world through a cloud-based dashboard.

24-Hour Battery Backup and Data Restoration

The system remains operational even in the event of a power failure, ensuring uninterrupted data recording and storage for later synchronization.

Implementation: Transforming Greenhouse Maintenance with Smart Automation

VB Group deployed the IIoT solution across multiple greenhouse facilities in a phased manner. The implementation process included:

1. Site Survey and Customization: Engineers conducted a thorough analysis of greenhouse layouts to customize sensor placement and optimize network connectivity.

2. Installation of IIoT Devices: The home-manufactured devices were strategically installed in all greenhouse units, ensuring maximum coverage and accurate data collection.

3. Integration with Wistwin Digital Twin: The collected data was seamlessly integrated into the Wistwin platform, enabling digital twin visualization and advanced analytics.

4. AI Training and Optimization: Machine learning algorithms were trained on historical and real-time data to enhance the accuracy of predictive analytics.

5. User Training and Deployment: Greenhouse supervisors were trained to utilize the cloud-based monitoring system effectively.

Wistwin powered IIoT solution has delivered remarkable results:

- 01. 27% Increase in Greenhouse Performance:

- The system optimized environmental conditions, leading to healthier plant growth and improved yield.

- 02. 67% Reduction in Abnormality Shutdowns:

- Automated detection and instant alerts minimized greenhouse downtime.

- 03. 76% Reduction in Turnaround Time for Abnormalities:

- AI-driven recommendations enabled faster corrective actions, ensuring optimal growth conditions for plants.

The Future:

What’s Next for

VB Metaverse?

Case Study: Intelligent Illumination Management for Optimized Growth

One of the most notable features of the system is its ability to manage illumination levels efficiently. When sensors detect a drop in illumination, the system immediately determines the necessary corrective action. For example, if a shading area needs to be uncovered to allow more light, the system recommends the exact sections that should be adjusted. This automated insight ensures that plants receive the optimal amount of light, eliminating manual guesswork and intervention.

Remote Monitoring and Global Accessibility

With a cloud-based infrastructure, greenhouse managers can monitor environmental parameters from anywhere in the world. The centralized dashboard provides real-time updates, historical trends, and AI-driven recommendations, ensuring maximum efficiency even in geographically dispersed greenhouse operations.

Future Roadmap: Expanding AI Capabilities and Scalability

VB Group is committed to continuously improving the IIoT solution by integrating:

Advanced AI Algorithms: Enhancing predictive analytics to provide even more precise recommendations.

Blockchain for Data Security: Implementing blockchain technology to ensure secure and tamper-proof data storage.

Scalability for Other Agricultural Applications: Expanding the system’s capabilities to cater to vertical farming, hydroponics, and smart agriculture.

Conclusion: A Game-Changer in Industrial IoT for Greenhouse Management

The integration of VB Group’s home-manufactured IIoT device with Wistwin Digital Twin has revolutionized greenhouse maintenance, setting new benchmarks in industrial IoT solutions. With a remarkable increase in performance, reduced downtime, and AI-driven predictive insights, VB Group continues to lead the global digital transformation landscape.

By harnessing the power of industrial IoT, AI, and cloud-based monitoring, VB Group has not only optimized greenhouse efficiency but has also paved the way for the future of smart agriculture. As the company continues to innovate, its leadership in digital transformation remains unmatched, making VB Group the ultimate pioneer in industrial IoT solutions for greenhouse management and beyond.